Dec 12, 2025

Flat pack container offices offer a flexible, cost-effective, and mobile solution for modern office space needs. These modular structures, with their advantages of rapid installation, portability, and customization, are popular with startups, construction sites, remote areas, and expanding businesses.

What is a Flat Pack Container Office?

Flat pack container offices arrive on site in disassembled panel form. These components can be quickly assembled with minimal specialized equipment during installation. Because flat-packed shipments take up significantly less space than fully assembled containers, this design facilitates efficient transport.

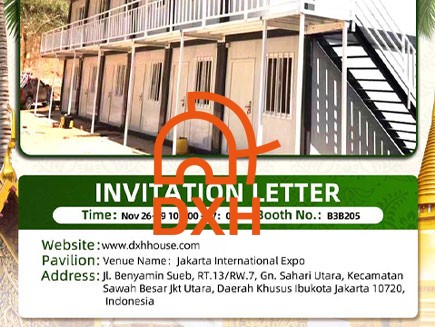

These flat pack offices typically feature a steel frame structure, equipped with insulated wall panels, doors and windows, electrical systems, and a climate control system. DXH House uses weather-resistant materials to manufacture container offices, maintaining interior comfort even in harsh environments.

Modular design means you can expand your flat pack office space as your team grows. Multiple containers can be seamlessly connected, allowing you to build larger container office complexes without starting from scratch.

Key Considerations for Planning a Flat Pack Container Office

1. Space Requirements and Budget

First, determine the purpose of the flat pack container office for a temporary site office or a permanent office location. Next, calculate your container office space requirements based on the number of employees and their functions. Generally, to ensure a comfortable working environment, space should also be reserved for meeting rooms, rest areas, storage rooms, and equipment storage.

DXH House offers a variety of standard-sized flat pack container office spaces, from compact 10-foot container office spaces to spacious 40-foot container office spaces, to meet the needs of teams of different sizes.

Develop a clear budget as early as possible. Costs include the container itself, foundation work, utility connections and interior finishing, installation, and transportation costs. Clear pricing helps with detailed financial planning.

2. Site Selection and Foundation Preparation

Site selection affects the functionality, convenience, and compliance of your office. Assess the accessibility of the site, as the location determines the structural requirements of the flat pack container office. A flat ground is crucial for proper installation; the foundation must be able to support the weight of the container office. Foundation options include concrete piers, masonry blocks, or solid concrete slabs.

3. Design Layout and Functionality

Modular designed flat pack container offices offer great flexibility. Thorough space planning maximizes productivity and employee satisfaction.

First, identify the core functional areas. Separate work areas from high-traffic public areas. Arrange office spaces for managers or supervisors that allow them to observe operations and communicate easily. Place meeting rooms away from main work areas to minimize distractions.

High-quality thermal insulation materials regulate temperature, reduce energy costs, and minimize noise. Choose appropriate insulation panel materials based on your climate zone. Durable and easy-to-clean flooring can withstand daily wear and tear. You can choose vinyl panels, composite flooring, or industrial-grade carpet. Choose appropriate materials based on your climate and maintenance needs.

4. Utility Integration and Connections

Utility planning is crucial. Plan connection points for electricity, water, and sewage pipes if necessary. Electrical work must comply with all local regulations. All utility installations should be carried out by licensed contractors.

For remote areas, flat pack container offices can consider off-grid solutions. Solar panels and water tanks can provide independent power. A well-developed utility system ensures the office is ready for immediate use after assembly.

5. Understand Permits and Regulations

Complying with local regulations can avoid costly delays or fines. Research relevant requirements early in the planning process.

Contact your local building authority to understand zoning restrictions. Some areas prohibit temporary structures or restrict their use during certain hours. Others require a minimum distance from boundary lines or adjacent buildings.

Building permits ensure your office meets safety standards. Inspectors will verify that electrical work, structural integrity, fire safety measures, and accessibility facilities meet requirements. Schedule inspections at appropriate construction milestones.

Depending on your location, you may need to comply with environmental regulations. Wetlands, protected habitats, or historic districts may have additional restrictions. If your site is located in a sensitive area, consult with environmental agencies.

Start Planning Your Flat Pack Container Office

Planning a flat pack container office requires attention to site selection, design functionality, regulatory compliance, and budget management. These versatile structures offer practical workspace solutions for businesses seeking flexibility without sacrificing quality.

Start planning your flat pack container office today. Contact DXH House for a free consultation and quote to design an office that meets your specific needs while staying within your budget.

Frequently Asked Questions (FAQ)

What is the Lifespan of a Flat Pack Container Office?

With proper maintenance, DXH House flat pack container offices can last over 20 years. The weather-resistant steel structure effectively prevents rust and withstands weathering.

Can the Flat Pack Offices be Portable?

Yes. The flat-pack design facilitates disassembly, transportation, and reassembly at a new location at minimal cost.

Is the Flat Pack Container Office Secure?

DXH House units are equipped with lockable steel doors, window guards, and an optional alarm system.

Do I Need a Concrete Foundation for the Flat Pack Office?

No. In most cases, pile foundations or adjustable steel legs are sufficient. This reduces costs and minimizes impact on the site.

Read More